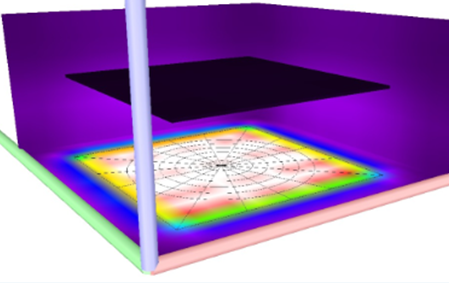

UV LED Goniophotometer

Laboratory

During the process of importing UV LED

illumination system, it can help customers about

cost control, process efficiency improvement. The

database of carbon reduction to replace mercury

lamp is clearer and the material partners will know

easily how to adjust the formula.

illumination system, it can help customers about

cost control, process efficiency improvement. The

database of carbon reduction to replace mercury

lamp is clearer and the material partners will know

easily how to adjust the formula.

UVC-UVA visible light ( 200nm - 800 nm ) Kilo-watt

UV illuminator system measured by goniophotometer.

We develop the system based on required beam angle,

radiant energy, uniformity from customers.

UV illuminator system measured by goniophotometer.

We develop the system based on required beam angle,

radiant energy, uniformity from customers.

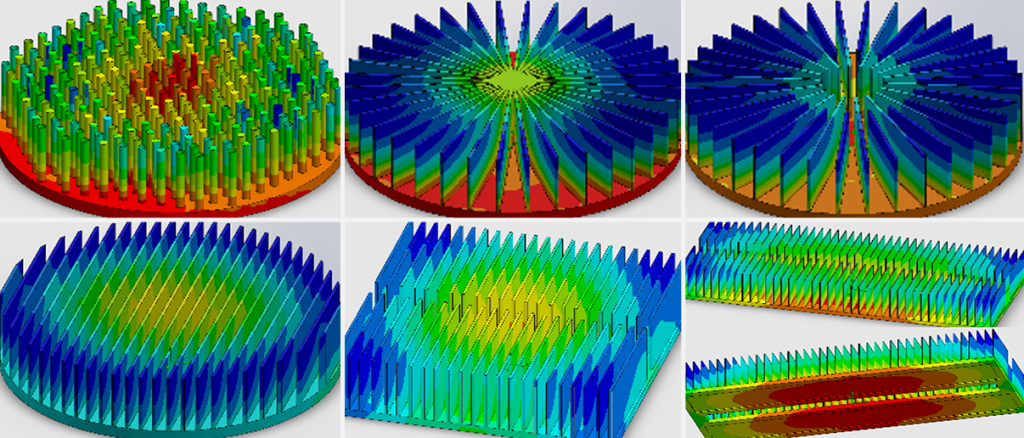

Optical Design Ability

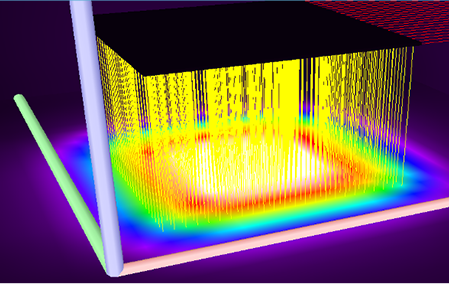

Through optical design to reach the energy transformation which traditional mercury lamp couldn't reach and lower the heat at the same time.

Utilizing quartz optical lens technology to inject UV LED energy into material interlayers.

Also matching the special adhesive for UV LED spectrum to carry on the procedure of modifying, bonding, and curing.

Also matching the special adhesive for UV LED spectrum to carry on the procedure of modifying, bonding, and curing.

The optical design of quartz with similar collimated beam can go through the fabrics to increase the lux and reach joule accumulation between fabriclayers.

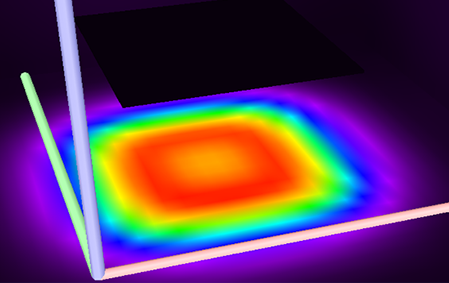

Calculation of UV energy distribution and energy Joule accumulation at the target position

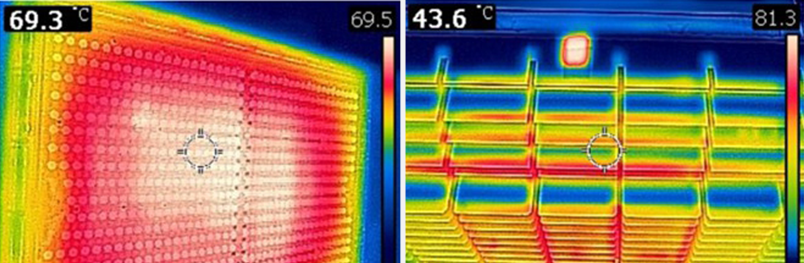

Thermal Simulation Engineering is a technical collaboration with

National Cheng Kung University

Thermal image from

actual measurement

actual measurement

UV LED radiation

integrating sphere.

Measuring range: UVC~UVA, visible wavelength 200nm~800nm

Provide completed optical information including mW, mW/cm2, mJ , IES fle, and thermal image to customer.

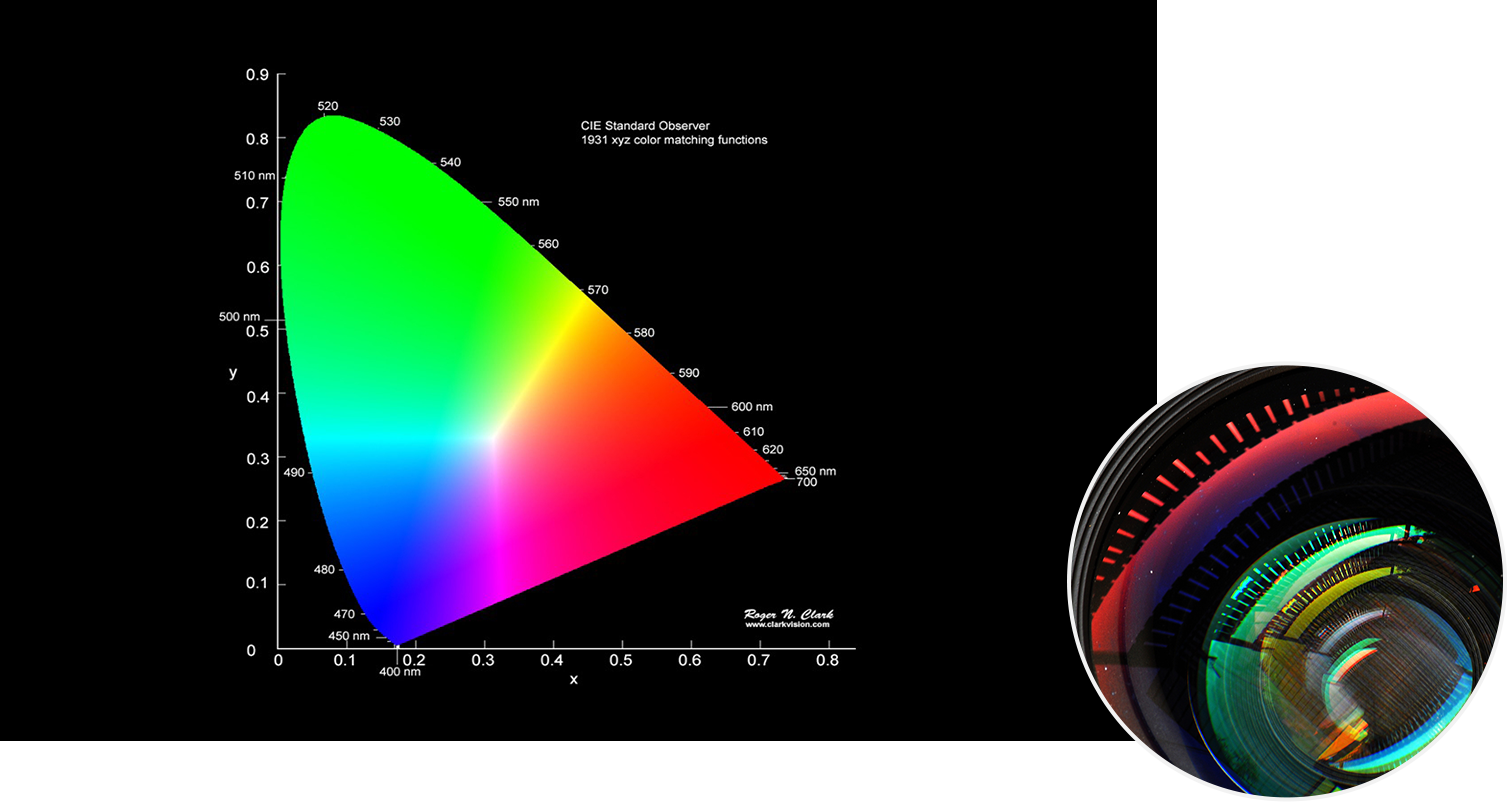

Special LED Package Technology-

Lighting Source for CMOS Calibration.

Imagesensorformachinevisionapplications. CIE3extremepointspolycrystalinepackages.

Similarcolimatedbeam design+controlviasoftware.

UV LED defecting inspection system.

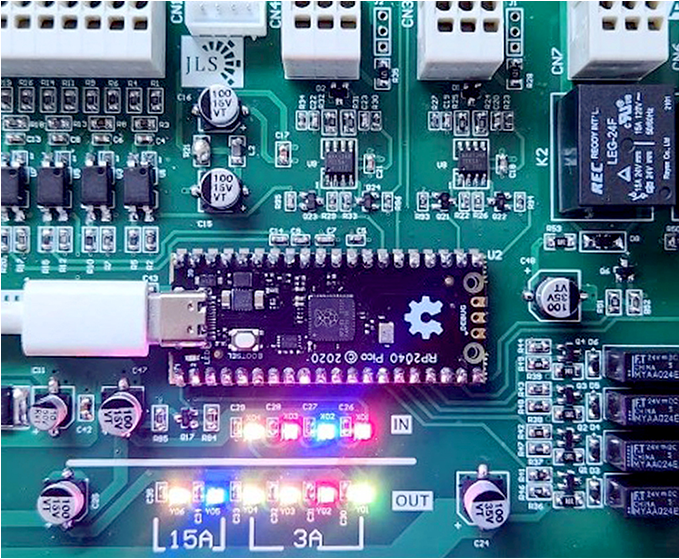

Customized MCU and IC module

developing and manufacturing.

Customized HMI with different languages and

microcontroller board to replace PLC.

Integrate HMI total solution with lower cost, larger

capacity RAM, and steadier transmission

microcontroller board to improve limited expansion

issues of old PLC. It can help customers collect the

industry 4.0 cloud information and ESG energy

consumption data through rapid wireless transmission

of microcontroller board.

microcontroller board to replace PLC.

Integrate HMI total solution with lower cost, larger

capacity RAM, and steadier transmission

microcontroller board to improve limited expansion

issues of old PLC. It can help customers collect the

industry 4.0 cloud information and ESG energy

consumption data through rapid wireless transmission

of microcontroller board.

UV Modifying

UV LED application to

replace mercury lamp.

replace mercury lamp.

UVC Cleaning

UV LED application to

replace mercury lamp.

replace mercury lamp.

UV Curing

UV LED application to

replace mercury lamp.

replace mercury lamp.

UV Defecting

Inspection

Special spectrum LED &

applications of UV LED

inspection lighting source.

applications of UV LED

inspection lighting source.